Industrial Encoders – Precision Feedback for CNC and Automation Systems

In modern CNC machines, robotics, and industrial automation, precision and accuracy are essential. This is where encoders come in. An encoder is a sensing device that converts motion—such as position, speed, or rotation—into electrical signals that can be interpreted by a control system.

Encoders serve as the “feedback eyes” of automation equipment, allowing machines to know exactly where they are and how fast they are moving. Without encoders, achieving the level of accuracy, efficiency, and safety demanded by today’s industries would be impossible.

At Keylux, we supply a wide range of genuine industrial encoders from trusted global brands such as Siemens, Fanuc, and Mitsubishi. Whether you need a rotary encoder for a CNC motor, a linear encoder for robotics, or a high-performance absolute encoder, Keylux provides reliable solutions backed by professional support.

How Encoders Work

The working principle of encoders revolves around detecting movement and converting it into measurable electrical signals.

- Motion Detection – Encoders use optical, magnetic, or mechanical systems to track position or rotation.

- Signal Conversion – Movement is translated into electrical pulses or digital data.

- Data Output – The encoder sends signals to the control system (PLC, CNC controller, or servo driver).

- Feedback Loop – The system uses this information to adjust motion, ensuring accuracy and stability.

There are different types of encoders used in industrial automation:

- Rotary Encoders – Measure angular rotation, speed, and shaft position.

- Linear Encoders – Detect straight-line movement with high precision.

- Incremental Encoders – Provide relative position data, often used for speed and direction feedback.

- Absolute Encoders – Deliver exact position information, even after power loss, ensuring maximum accuracy.

By integrating encoders into automation systems, industries achieve closed-loop control, where machines self-correct in real time to maintain precise operation.

Applications of Encoders

Encoders are widely used across industries that demand precision, reliability, and repeatability.

The advantages of using encoders in automation systems include:

- Higher accuracy for machining and manufacturing.

- Improved safety by preventing mechanical errors.

- Energy efficiency through optimized motor control.

- Reduced downtime with reliable feedback for diagnostics.

CNC Machines

Encoders provide spindle and axis feedback for cutting, milling, and drilling with extreme precision.

Robotics

Enable smooth, accurate multi-axis movement and joint control.

Industrial Motors and Drives

Monitor speed and torque for optimized performance.

Packaging and Textile Machinery

Maintain synchronization for consistent quality.

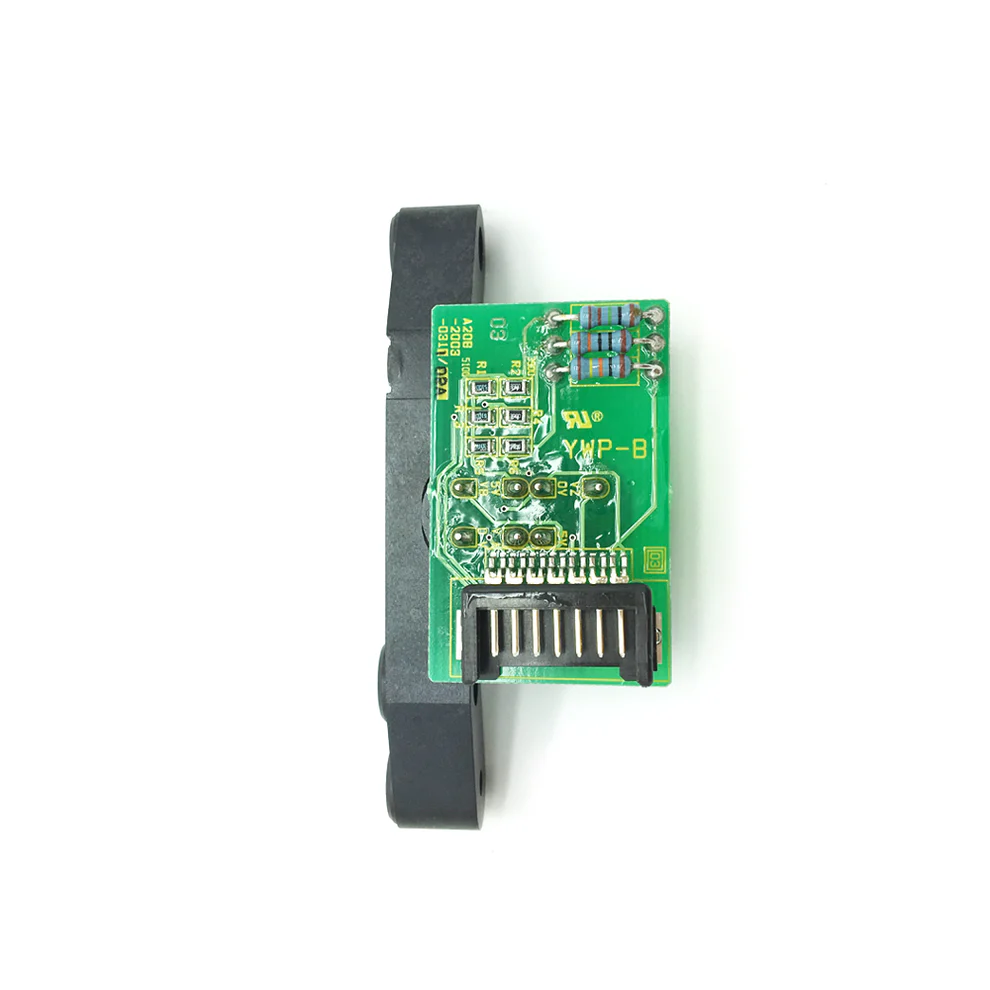

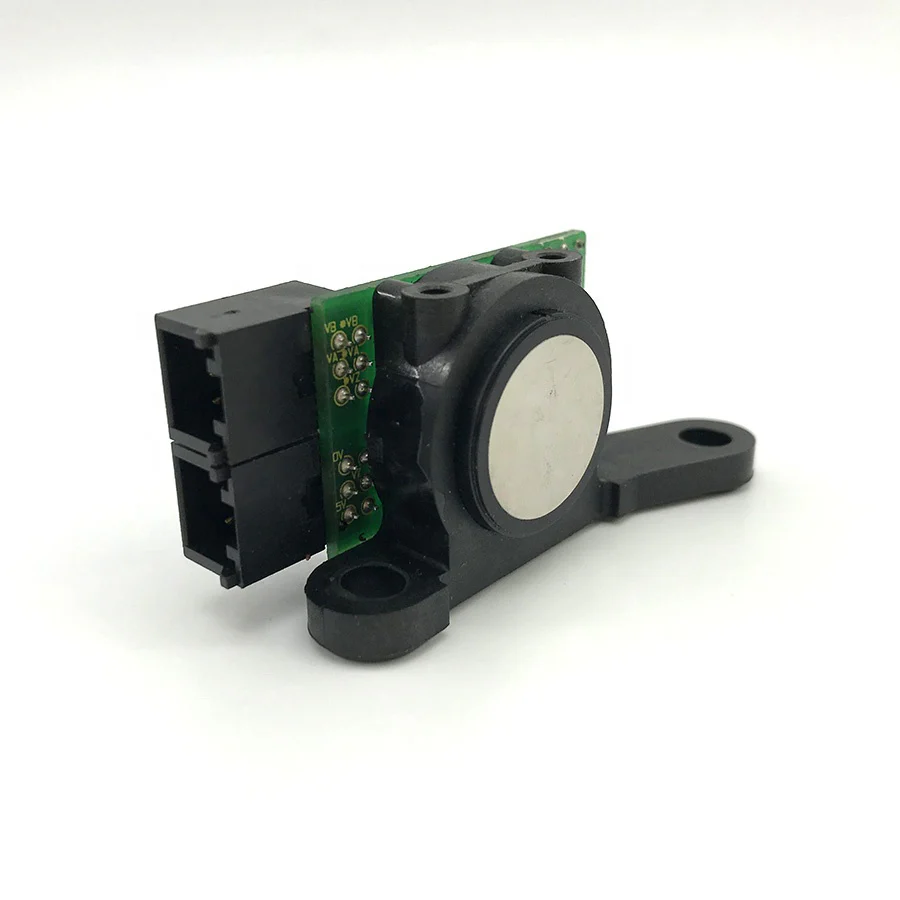

Keylux Featured Encoders

Why Choose Keylux for Encoders

At Keylux, we understand that encoders are mission-critical for industrial automation. That’s why we only supply authentic, high-quality products trusted by manufacturers worldwide.

Here’s why customers rely on Keylux for encoders:

Genuine OEM Products

100% original Siemens, Fanuc, Mitsubishi, and other encoder brands.

Extensive Inventory

Wide selection of rotary, linear, incremental, and absolute encoders.

Competitive Pricing

Cost-effective solutions for businesses of all sizes.

Global Reach

Serving both domestic (China) and international customers with fast, reliable delivery.

Technical Expertise

Our team helps you select and integrate the right encoder for your automation needs.

By sourcing encoders from Keylux, you gain a trusted partner dedicated to quality, performance, and long-term reliability in automation systems.

KEYLUX – Genuine Automation Parts. Fast. Reliable. Worldwide.

Keylux is your one-stop global supplier for automation brands that manufacturers trust.