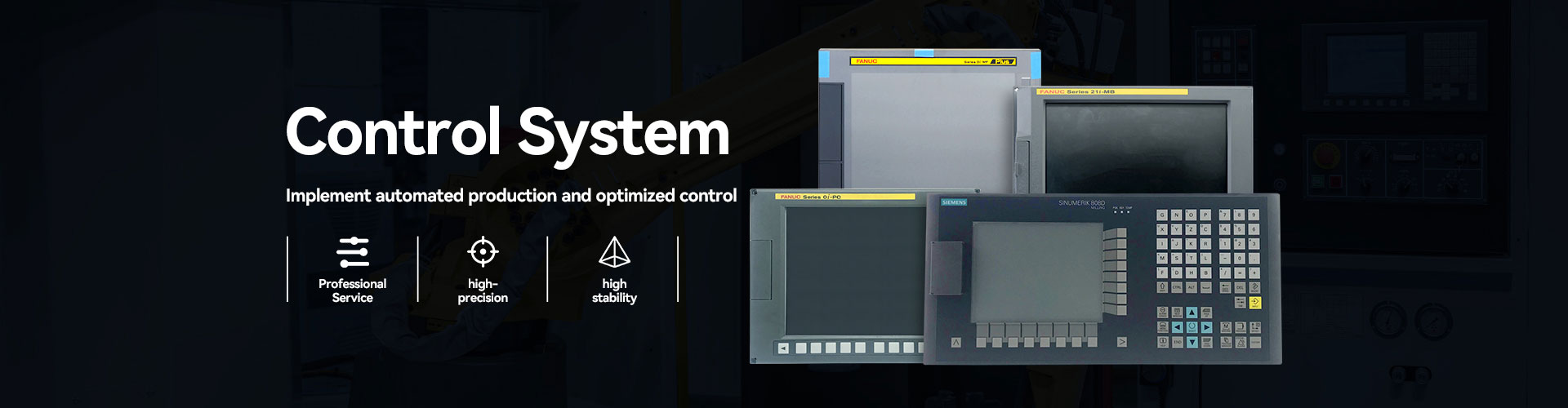

Industrial Control Systems – Precision and Reliability in Automation

In today’s fast-paced industrial environment, efficiency, accuracy, and safety are non-negotiable. At the core of these requirements lies the industrial control system (ICS) — a framework of devices and components that manages, regulates, and optimizes machines and processes.

A control system ensures that everything from CNC machines and robotic arms to power plants and packaging lines operates smoothly and consistently. By continuously monitoring inputs, processing signals, and executing outputs, control systems are the backbone of industrial automation.

At Keylux, we supply high-quality, genuine control system components from leading global brands such as Siemens, Fanuc, and Mitsubishi, empowering businesses with reliable, cost-effective, and future-ready automation solutions.

How Control Systems Work

The working principle of a control system can be summarized as input–process–output.

- Inputs – Sensors, transducers, and measuring devices collect real-time data on variables such as temperature, pressure, speed, and position.

- Processing – The controller (PLC, DCS, or CNC control unit) interprets this data using programmed logic and compares it to set parameters.

- Outputs – Commands are sent to actuators, motors, valves, or other devices to make corrections and maintain stability.

Control systems are broadly classified into:

- Open-loop systems – Execute commands without feedback (simpler but less precise).

- Closed-loop systems – Use continuous feedback to minimize errors and achieve high precision.

In modern automation, control systems integrate with PLCs, HMIs, servo drivers, and inverters, creating a seamless ecosystem for monitoring, decision-making, and execution. The result is improved efficiency, reduced downtime, and enhanced product quality.

Applications of Control Systems

Industrial control systems are vital in almost every sector, enabling consistent performance and operational safety.

By implementing advanced control systems, industries achieve:

- Higher efficiency through optimized operations.

- Reduced downtime with predictive monitoring.

- Cost savings from lower energy consumption.

- Enhanced safety and compliance, protecting both workers and end products.

CNC Machining and Robotics

Monitor multi-axis movements, adjust speeds, and control operations with precision.

Manufacturing Lines

Automating assembly, welding, painting, and packaging processes.

Energy and Utilities

Power generation, smart grids, water treatment, and renewable integration.

Oil, Gas, and Chemicals

Monitoring pressure, flow, and temperature for safety and efficiency.

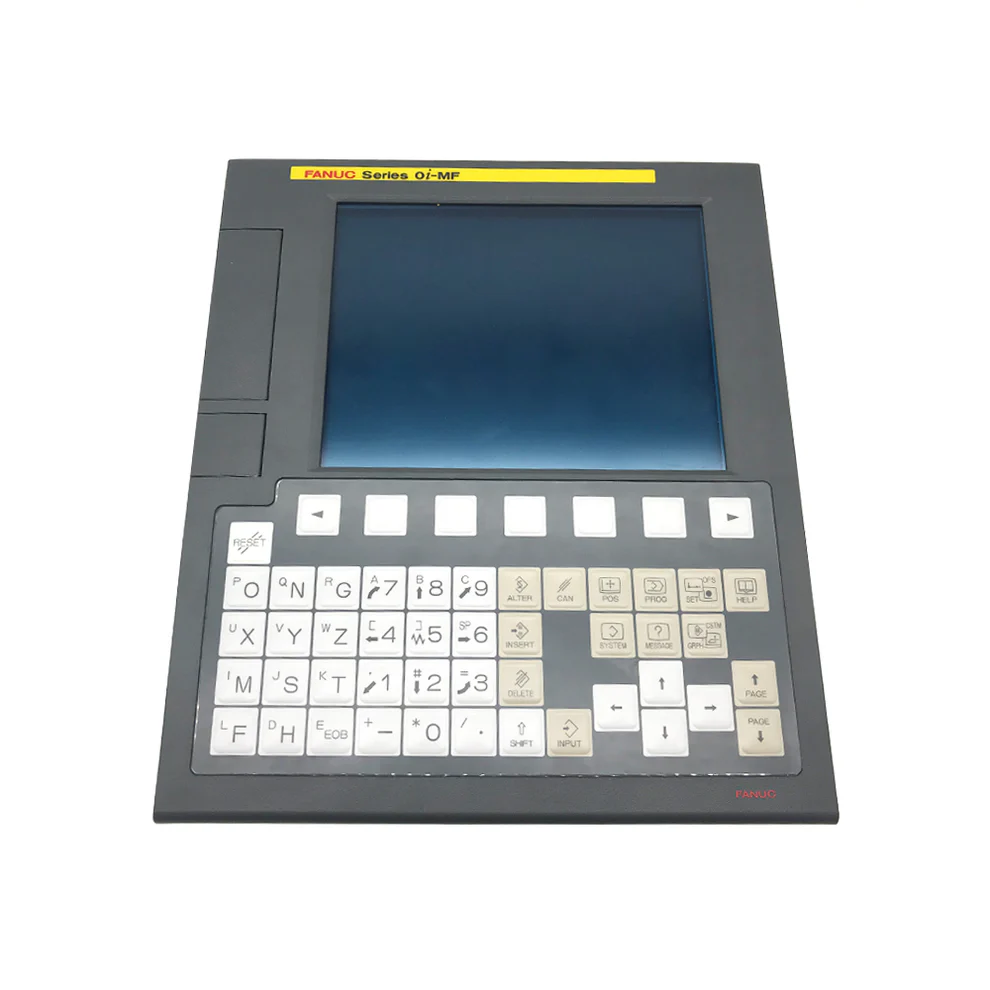

Keylux Featured Control Systems

Why Choose Keylux for Control Systems

At Keylux, we understand that reliable control systems are the foundation of successful automation. That’s why we offer more than just parts — we provide complete solutions for global customers.

Here’s why businesses worldwide trust Keylux:

Authenticity Guaranteed

100% original control modules, PLCs, HMIs, servo drivers, and inverters from Siemens, Fanuc, Mitsubishi, and other global brands.

Extensive Inventory

A wide selection of components ready to ship, covering diverse automation requirements.

Competitive Pricing

Cost-effective solutions that balance affordability with top-tier performance.

Global Reach

Trusted by customers in China and across international markets with efficient logistics.

Technical Expertise

Our skilled engineers provide guidance in selecting and integrating the right control systems for your applications.

By partnering with Keylux, customers gain access to high-performance control systems that ensure precision, safety, and long-term reliability — all backed by professional service.

KEYLUX – Genuine Automation Parts. Fast. Reliable. Worldwide.

Keylux is your one-stop global supplier for automation brands that manufacturers trust.