Teach Pendants – Simplifying Programming for CNC and Robotics

In modern CNC machining, robotics, and industrial automation, intuitive control is essential for efficiency and precision. A teach pendant is a handheld programming device that enables operators to directly interact with machines and robots, guiding them step by step through tasks.

By using a teach pendant, operators can manually program movements, test processes, and fine-tune automation without the need for complex coding. This makes teach pendants a cornerstone of robot programming, CNC setup, and machine calibration.

At Keylux, we provide a wide selection of genuine teach pendants from leading global brands such as Fanuc, Siemens, and Mitsubishi, ensuring our customers enjoy authentic quality, seamless integration, and reliable performance.

How Teach Pendants Work

The working principle of a teach pendant lies in its ability to translate operator inputs into machine commands.

- User Input – Operators use buttons, joysticks, or touchscreens to guide the machine or robot through specific paths.

- Recording Movements – The pendant records these manual steps, creating a sequence of programmed instructions.

- Program Execution – The stored instructions are transferred to the machine’s main controller (PLC, CNC control, or robotic controller).

- Testing and Adjustment – Operators can safely test processes and adjust parameters in real time.

Teach pendants are designed with safety features such as deadman switches and emergency stops, ensuring secure operation during programming. They are also highly user-friendly, enabling both experienced engineers and newer operators to configure machines quickly and efficiently.

By integrating with robot controllers, CNC units, and automation systems, teach pendants allow manufacturers to achieve greater flexibility, accuracy, and productivity.

Applications of Teach Pendants

Teach pendants are indispensable across industries where automation and robotics play a critical role.

The benefits of using teach pendants include:

- Reduced setup time compared to complex offline programming.

- Greater accuracy in robotic path teaching and CNC control.

- Improved safety with built-in protective features.

- Operator-friendly usability, reducing training requirements.

In industries where flexibility and precision are crucial, teach pendants give manufacturers the ability to adapt processes quickly without sacrificing quality.

Robotics

Teaching robots precise movements for welding, painting, assembly, and pick-and-place operations.

CNC Machining

Guiding machine tools in creating tool paths, setting offsets, and optimizing cutting processes.

Automation Systems

Programming conveyors, packaging equipment, and material-handling systems.

Maintenance and Troubleshooting

Manually controlling equipment during inspections or repairs for safety and accuracy.

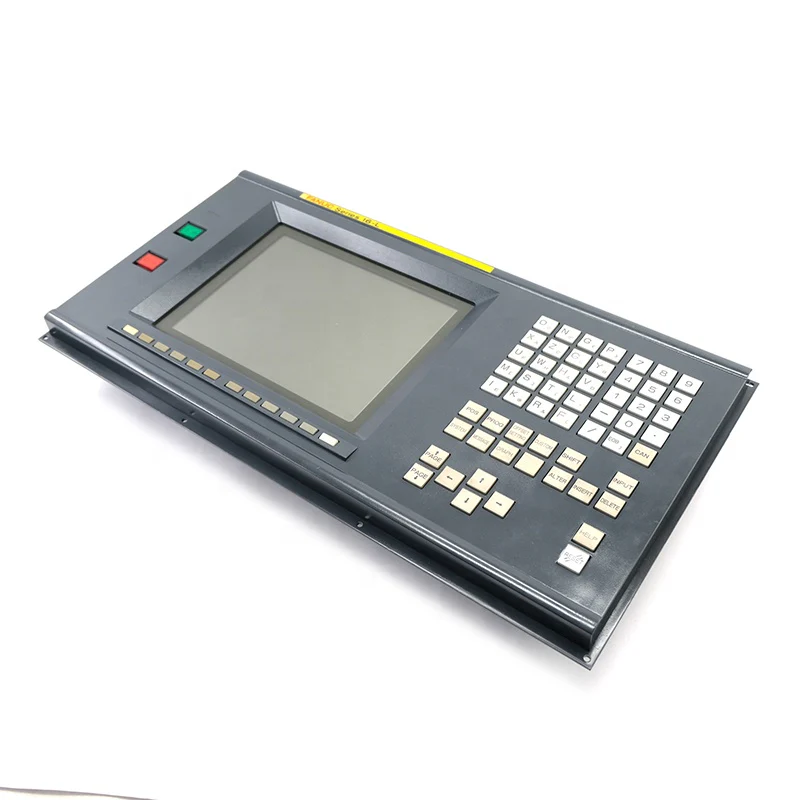

Keylux Featured Teach Pendants

Why Choose Keylux for Teach Pendants

At Keylux, we understand that teach pendants are vital to ensuring smooth and precise automation operations. That’s why we only supply authentic, high-performance products trusted by global manufacturers.

Here’s why customers choose Keylux:

Authenticity Guaranteed

100% original teach pendants from Fanuc, Siemens, Mitsubishi, and other leading brands.

Extensive Inventory

Models compatible with a range of CNC machines, industrial robots, and automation systems.

Competitive Pricing

Cost-effective solutions for replacements, upgrades, and bulk procurement.

Global Reach

Serving clients across China and international markets with fast, reliable delivery.

Technical Expertise

Our team helps businesses select and integrate the correct teach pendant for their systems.

Whether you need a Fanuc robotic teach pendant, a Siemens CNC controller pendant, or a Mitsubishi automation pendant, Keylux ensures top-quality products backed by professional service.

KEYLUX – Genuine Automation Parts. Fast. Reliable. Worldwide.

Keylux is your one-stop global supplier for automation brands that manufacturers trust.