Industrial Circuit Boards – The Core of Automation and CNC Systems

Every industrial automation system relies on one essential foundation: the circuit board. Also known as a Printed Circuit Board (PCB), this component forms the backbone of electronic control, ensuring that signals, data, and power are distributed efficiently throughout a system.

In CNC machines, robotics, energy systems, and automotive production, circuit boards provide the structure and connectivity that allow processors, sensors, and actuators to work together seamlessly. Without them, advanced automation would not be possible.

At Keylux, we supply genuine industrial circuit boards from world-leading brands such as Siemens, Fanuc, and Mitsubishi. With our expertise and global supply network, we help businesses maintain reliable performance, minimal downtime, and cost-effective automation solutions.

How Circuit Boards Work

The working principle of a circuit board is simple yet indispensable: it provides the electrical pathways that connect and control the various components of an automation system.

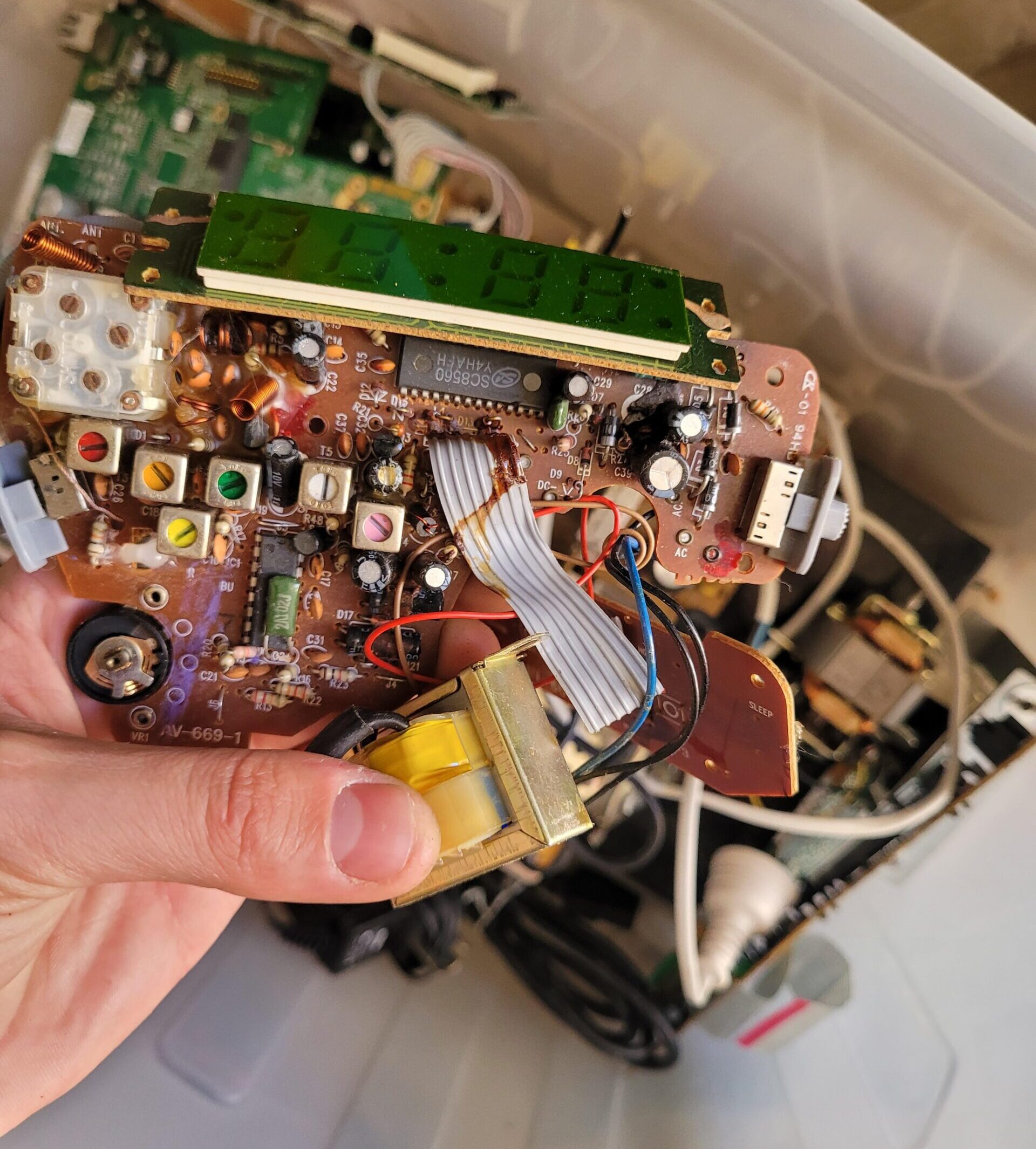

A typical industrial PCB consists of:

- Conductive tracks – pathways that route signals and power between components.

- Electronic components – resistors, capacitors, transistors, ICs, and connectors.

- Layers – single-layer boards for simple applications, or complex multi-layer PCBs for advanced CNC and automation systems.

- Power distribution – integrated voltage layers ensure a consistent power supply to all devices.

Circuit boards can be rigid, flexible, or hybrid designs, depending on the environment and application. In industrial automation, they are integrated into PLCs, HMIs, servo drivers, and inverters, ensuring smooth communication and precise control.

By acting as the nervous system of automation, circuit boards enable real-time data transmission, signal accuracy, and long-term operational stability.

Applications of Circuit Boards

Circuit boards are used in almost every sector of industrial automation, from precision CNC machining to large-scale process control.

Benefits of using industrial-grade PCBs include:

- Compact design – reduces equipment footprint.

- High reliability – withstands harsh industrial conditions.

- Scalability – adaptable for simple or complex automation systems.

- Durability – built to resist heat, dust, and vibration in manufacturing environments.

CNC Machines

Control boards manage spindle motors, servo drivers, and precision machining tasks.

Robotics

Compact PCBs handle motion control, sensor input, and real-time calculations.

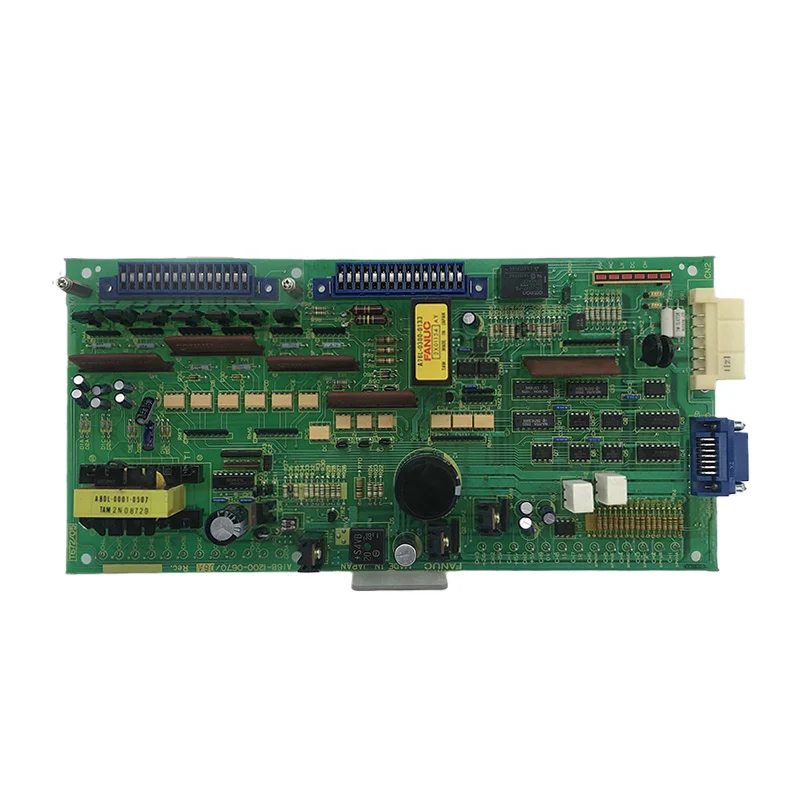

Inverters and Drives

Power PCBs regulate voltage and current for motors and automation systems.

Energy and Utilities

PCBs enable monitoring and conversion in renewable energy inverters, turbines, and grid systems.

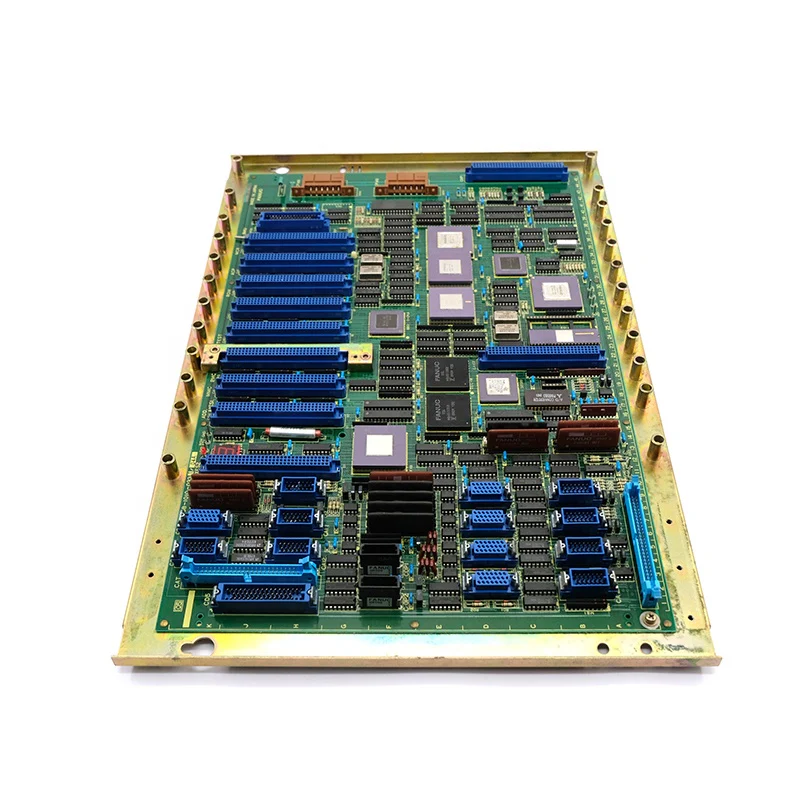

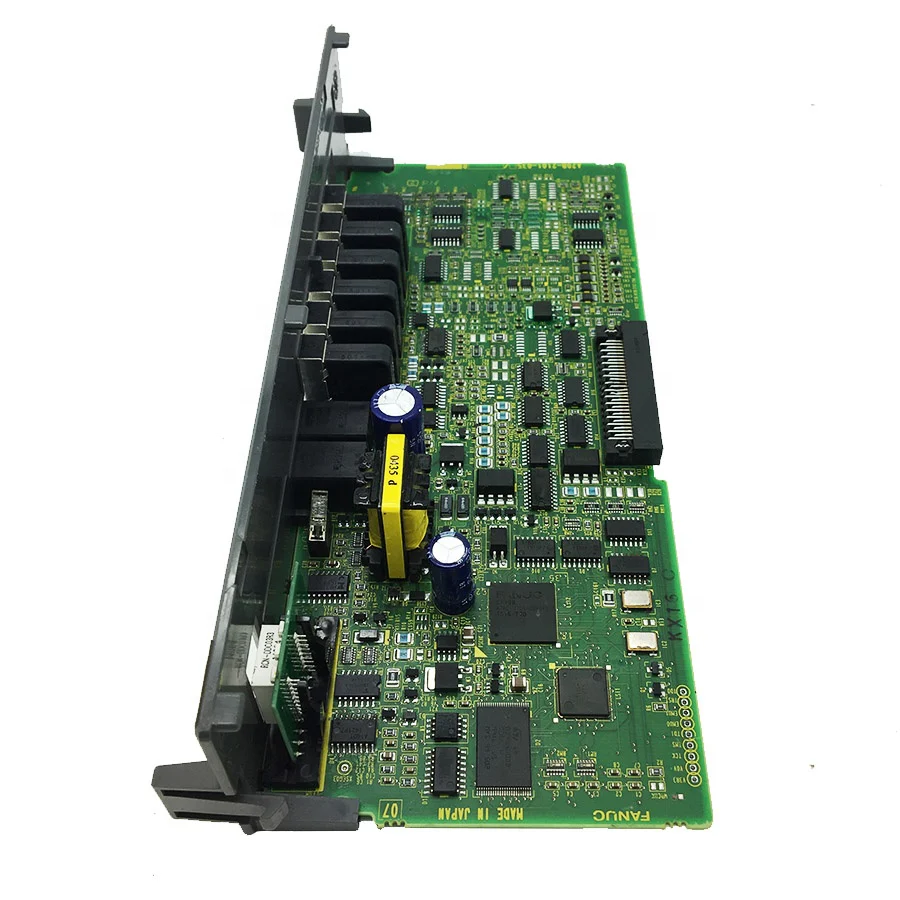

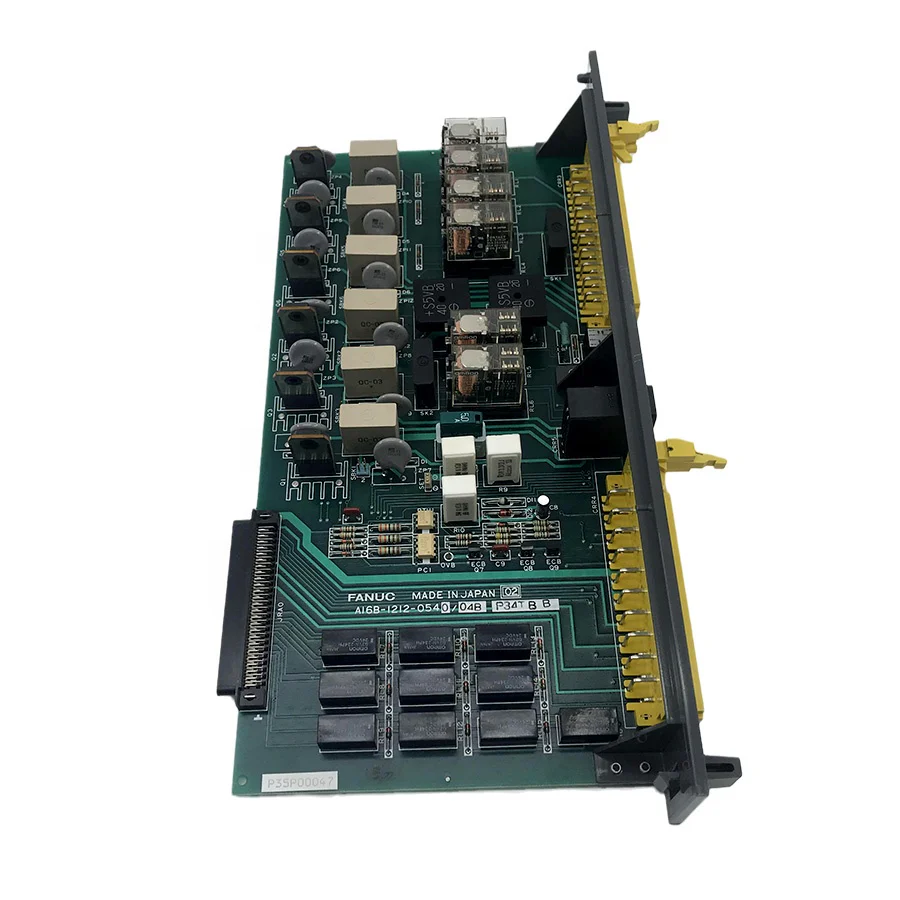

Keylux Featured Circuit Boards

Why Choose Keylux for Circuit Boards

At Keylux, we understand that circuit boards are not just components — they are the core of every automation system. That’s why customers worldwide rely on us for quality, authenticity, and service.

Here’s why Keylux is the preferred choice:

Authenticity Guaranteed

100% original PCBs and control boards from Siemens, Fanuc, Mitsubishi, and other global leaders.

Extensive Inventory

Wide selection of circuit boards for CNC machines, robotics, inverters, and industrial automation.

Competitive Pricing

Affordable, value-driven solutions without compromising quality.

Global Reach

Fast, reliable delivery across China and to international customers.

Technical Expertise

Our specialists help businesses choose and integrate the right circuit board for their systems.

Whether you need a replacement PCB for a CNC machine, a control board for robotics, or a power board for inverters, Keylux provides solutions that guarantee long-term reliability and performance.

KEYLUX – Genuine Automation Parts. Fast. Reliable. Worldwide.

Keylux is your one-stop global supplier for automation brands that manufacturers trust.